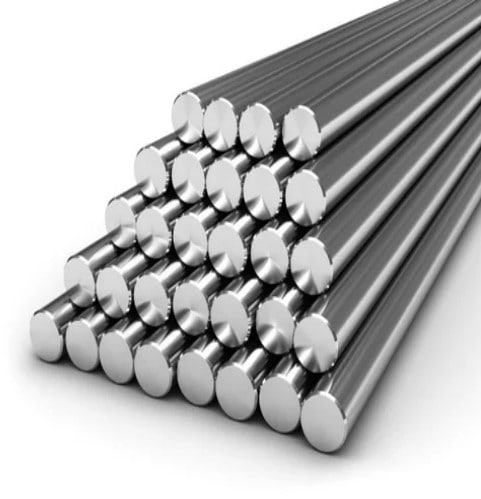

F53 (2507) Super Duplex Stainless Steel

UNS S32750F53 (2507) Super Duplex Stainless Steel

F53 (2507) Super Duplex Stainless Steel is an austenitic-ferritic (duplex) stainless steel. Consisting of 25% Chromium and 7% Nickel. F53 (2507) Super Duplex Stainless Steel, like other duplex grades combines higher corrosion resistance and strength compared to other austenitic stainless steels, while also having superior pitting resistance. F53 (2507) Super Duplex Stainless Steel boasts higher impact strengths over F51, It is also suitable in applications in environments of -50°F to +600°F temperature range. Like other duplex grades, F53 (2507) Super Duplex Stainless Steel does suffer from embrittlement and loss of toughness, when exposed to prolonged use in applications or environments below -50°F or above +600°F, this is why F53 (2507) Super Duplex Stainless Steel is not suitable for exposure outside of these ranges.

Common industry/applications for F53 (2507) Super Duplex Stainless Steel include: Oil & Gas equipment, Chemical and Biofluid processing, Pressure Vessels, and Mechanical and Structural.

Product forms include round bar, plate & sheet, and forgings.

Standards

- UNS S32750

Characteristics

- For use in -50F to +600F temperatures.

- Excellent corrosion & pitting resistance.

- Good cryogenic (-50F) impact strength

Physical Properties

- Density: 0.281LB/in³ (7.80g/cm³)

- Melting Point: 2570–2660°F (1410–1460°C)

- Modulus of Elasticity: 29.0x10⁶psi (200 GPa)

- Magnetic Permeability: less than 1.05 @ 68°F (20°C)

Chemical Composition

PREN: Pitting Resistance Equivalent Number: An Equation to correlate pitting resistances of product, based on chemistry. This equation is: Cr + (3.3 x Mo) + (16 x N) – PREN = less than 40

C

Mn

S

P

Si

Cr

Ni

Mo

N

Cu

Mechanical Properties: Wrought & Forged Bars

Charpy Impact: Temp: -50°F (-46°C) / Value: ≥33Ft-Lbs (≥45J)

Typical mechanical properties, actual minimums may vary based on processing.

KSI (MPa)

KSI (MPa)

HRC (BHN)

Specialty Steel Supply makes all reasonable efforts to ensure the accuracy and correctness of the data found on this website and the associated documents but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general information only and not for providing design advice. It is the responsibility of the user to test specific alloys under actual service conditions to determine their suitability for a particular purpose.

Stainless and Alloys

We collaborate to help you exceed requirements by bringing your best ideas forward and eliminating non-conformance.

Specialty Steel Supply Inc. is one of the largest distributors of austenitic, precipitation hardened, duplex and martensitic stainless steels. We have a wide range of products and types of stainless steel round bar and our well trained staff offers many years of experience in all aspects of the steel industry. Our ability to procure and source metals from all parts of the world allows us to stay competitive in a global marketplace. We are committed to developing and servicing just in time inventory programs.

Specialty Steel Supply

19201 Circle Lake Drive

Pinehurst, Texas 77362

info@specialtysteelsupply.com

Business Hours

Sunday - Closed